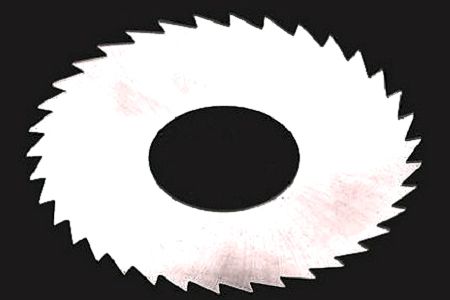

Saw Blade

Round Cutting Tools

Circular saw blades are usually made of wear-resistant materials such as high-speed steel (HSS) or tungsten steel (tungsten carbide). They are designed with a central hole that can pass through the tool bar, making them suitable for rotary cutting operations. Circular saw blades can effectively cut the surface or edges of workpieces to achieve cutting or grooving effects. Its service life will vary depending on the tooth design and number of teeth.

HSS saw blades have good flexibility and are not easy to break, so they are suitable for softer cutting environments; while tungsten steel saw blades have higher hardness and wear resistance and have a longer life, but are relatively brittle and prone to breakage. Therefore, users can choose between these two saw blades according to their needs.

HSS High Speed Steel Saw Blade

HSS high speed steel saw blade is a cutting tool made of high-speed steel. It is an alloy steel...

Tungsten Carbide Saw Blade

Tungsten carbide circular saw blade is a cutting tool made of tungsten carbide material. It is usually...

Saw Blade | CNC Machining Solutions with ISO-Certified Carbide Inserts – Guass

Enhance your machining accuracy and efficiency with high-performance Saw Blade engineered by Guass. Designed to handle challenging materials and high-speed operations, our inserts deliver consistent results across turning, milling, and drilling applications.

Whether you're working with hardened steel, stainless alloys, or composites, our ISO-certified solutions are trusted by manufacturers in aerospace, automotive, electronics, and plastic injection molding industries. Each insert is crafted for longevity, excellent chip control, and minimal downtime—making your CNC process faster and more cost-effective.

With over 15 years of expertise in tungsten carbide sintering and tool innovation, Guass continues to set the standard for precision tooling. Explore our full selection of carbide inserts built for maximum durability and performance.