Turning Insert

The operation of turning inserts typically involves controlling the movement of the insert on the workpiece to achieve the desired depth of cut, feed rate, and cutting speed. Insert selection and cutting parameter adjustment are critical to obtaining correct machining results and surface quality. Turning inserts are widely used in metal processing, manufacturing, machining and other fields, and are one of the indispensable tools in many machining operations.

Negative Turning Inserts

The characteristic of negative angle inserts is that the angle between the cutting surface...

Positive Turning Carbide Inserts

Positive turning carbide inserts are usually made from wear resistant materials such as carbide...

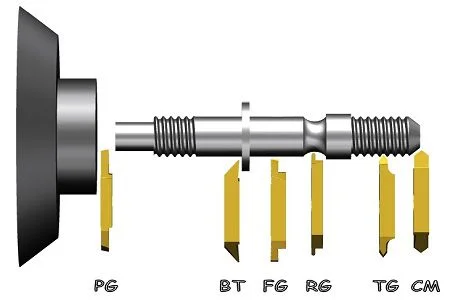

Grooving and Parting Off Carbide Inserts

Grooving and parting off carbide inserts are cutters used for grooving, parting and parting...

Threading Inserts

Threading inserts specialize in threading and often have special cutting geometries and edge...

Auto Lathe Machine Turning Insert

The auto lathe machine is a turning machine tool for high-precision centering, particularly...

Turning Insert | CNC Machining Solutions with ISO-Certified Carbide Inserts – Guass

Enhance your machining accuracy and efficiency with high-performance Turning Insert engineered by Guass. Designed to handle challenging materials and high-speed operations, our inserts deliver consistent results across turning, milling, and drilling applications.

Whether you're working with hardened steel, stainless alloys, or composites, our ISO-certified solutions are trusted by manufacturers in aerospace, automotive, electronics, and plastic injection molding industries. Each insert is crafted for longevity, excellent chip control, and minimal downtime—making your CNC process faster and more cost-effective.

With over 15 years of expertise in tungsten carbide sintering and tool innovation, Guass continues to set the standard for precision tooling. Explore our full selection of carbide inserts built for maximum durability and performance.