Grooving and Parting Off Carbide Inserts

Grooving carbide inserts / parting off carbide inserts

Grooving and parting off carbide inserts are cutters used for grooving, parting and parting off workpieces. These tools have special edge designs that can create long and narrow channels, grooves or parting lines on the workpiece. The edge design depends on the required cutting width and depth and can be adapted to different machining requirements.

Grooving and parting off carbide inserts are mainly used in the following situations:

- Grooving Processing: used to create long straight grooves on the surface of the workpiece.

- Cutting Off: used to cut workpieces into required sizes, such as cutting metal rods or pipes.

- Grooving: used to create narrow grooves on the surface of the workpiece, such as V-shaped grooves, U-shaped grooves, etc.

Grooving and parting cutters can be used on different types of materials, including metals, plastics, wood, etc., and enable efficient processing.

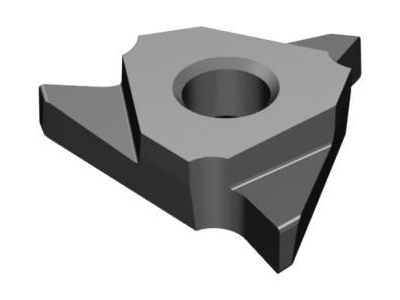

Right-Hand Thick Triangular Grooving Inserts

Right-hand thick triangular grooving inserts are essential tools for cutting, parting and grooving...

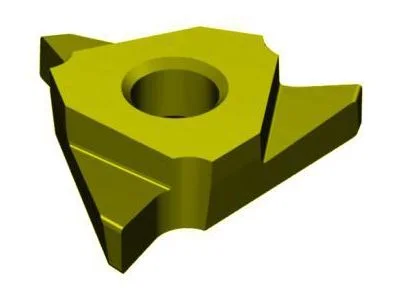

DetailsLeft Hand Thick Triangular Grooving Inserts

The left hand thick triangular grooving inserts are tools designed for cutting, parting and grooving...

DetailsLong Plate Grooving Inserts

The grooving and parting off carbide insert adopts Japanese precision surface treatment technology,...

DetailsGrooving and Parting Off Carbide Inserts | CNC Machining Solutions with ISO-Certified Carbide Inserts – Guass

Enhance your machining accuracy and efficiency with high-performance Grooving and Parting Off Carbide Inserts engineered by Guass. Designed to handle challenging materials and high-speed operations, our inserts deliver consistent results across turning, milling, and drilling applications.

Whether you're working with hardened steel, stainless alloys, or composites, our ISO-certified solutions are trusted by manufacturers in aerospace, automotive, electronics, and plastic injection molding industries. Each insert is crafted for longevity, excellent chip control, and minimal downtime—making your CNC process faster and more cost-effective.

With over 15 years of expertise in tungsten carbide sintering and tool innovation, Guass continues to set the standard for precision tooling. Explore our full selection of carbide inserts built for maximum durability and performance.