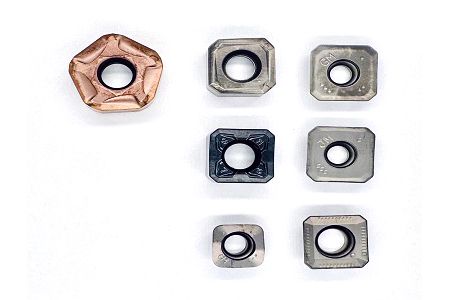

Milling Inserts

Carbide Inserts

Milling inserts are cutting tools used for milling processing, also known as cemented carbide. It is characterized by being able to withstand high-speed cutting and high-load applications. The blade design usually has a specific cutting geometry to achieve different cutting operations, which is mostly used in rough milling and has considerable advantages in removing workpiece material.

The milling blade has multiple cutting edges. After processing for a period of time, it can be rotated to another corner and the blade is replaced to extend the use time of the blade. The processing conditions are high depth of cut and low to medium speed to achieve high torque removal effect., the processed surface mostly has a flat micro-strip smooth cutting surface, the roughness is medium to upper, and it is also suitable for processing many different materials, including metals, plastics, composite materials, etc., generally speaking , this type of insert has high rigidity and stability to ensure cutting accuracy.

Face Milling Inserts

Face milling inserts are a type of cutting tool used for milling, also known as carbide inserts....

Profile Milling Inserts

Profile milling inserts, these inserts have an insert shape and edge design that allows them...

Shoulder Milling Inserts

Shoulder milling inserts have specific cutting geometries and edge designs for efficient shoulder...

Slotting Milling Inserts

Slotting milling inserts are usually made of carbide or ceramic materials, which have high...

High Feed Milling Inserts

High feed milling inserts feature special cutting geometries and edge designs to enable high-feed...

Unique Milling Inserts

Unique milling inserts have many unique features and their design and application are often...

Milling Inserts & Hobbing Inserts

Gear milling inserts & hobbing inserts are core components specially installed on gear milling...

Milling Inserts | CNC Machining Solutions with ISO-Certified Carbide Inserts – Guass

Enhance your machining accuracy and efficiency with high-performance Milling Inserts engineered by Guass. Designed to handle challenging materials and high-speed operations, our inserts deliver consistent results across turning, milling, and drilling applications.

Whether you're working with hardened steel, stainless alloys, or composites, our ISO-certified solutions are trusted by manufacturers in aerospace, automotive, electronics, and plastic injection molding industries. Each insert is crafted for longevity, excellent chip control, and minimal downtime—making your CNC process faster and more cost-effective.

With over 15 years of expertise in tungsten carbide sintering and tool innovation, Guass continues to set the standard for precision tooling. Explore our full selection of carbide inserts built for maximum durability and performance.