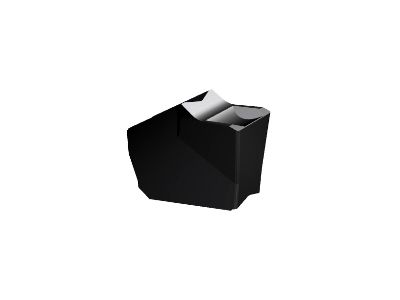

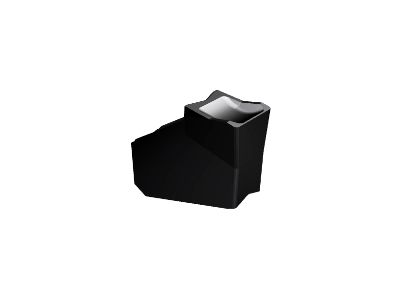

Long Plate Grooving Inserts

Adaptable Mitsubishi & Iscar Brand

The grooving and parting off carbide insert adopts Japanese precision surface treatment technology, with a highly accurate and clean appearance. It is equipped with a Swiss coating effect and the durability is increased by 30%. The American tungsten material ensures product quality consistency and stability, and the basic strength is increased by 50%. This long-fluted insert has a longer cutting edge for fast cutting and improved production efficiency. Mainly used for milling and turning operations, it can quickly and accurately divide workpieces into required sizes and shapes.

This insert is widely used in metalworking, construction, manufacturing and other industries. The multi-functional magnetic design has multiple cutting edges and can be used for a variety of machining tasks such as milling, grooving, side machining, etc., making it multi-purpose. We also offer up to 90% bespoke manufacture to meet different requirements and ensure that each blade meets the highest quality standards. Choose our ochre grooving and parting off insert and experience superior performance and reliability to help you increase productivity in a wide range of machining applications.

Characteristics and Applications

Grooving and parting off inserts are a cutting tool used for turning. Most insert shapes are long and striped. There is no specific ISO code. The systems of each brand are different. Picking up which insert depends on the outer or inner diameter of the operation, and whose system it is. The best known are the grooving and cutting blade systems, starting with the S and K series.

Ours is the M Series version, which is suitable for customers who are still using the M Series version of the tool holder. It is used on one side and has a total of 2 cutting edges. There are many shapes of chip grooves and the size of the cutting R angle There are many types and the shape of the groove to be used depends on the material to be machined.

DGM series are Japanese style; DGN, GTN, GFN are European style.

D & G Type

- GW1667, GFN3-MT

- GW1088A, GTN3-MT

- GW1553, DGM3020CT

- GW404, DGM4020CT

- GW1656, DGM5025CT

- GW1609, DGM3020CTF

- GW1598, DGM4020CTF

- GW1657, DGM5025CTF

- GW1669, DGN3025CE

- GW1793, DGN3102MT

- GW1825, DGN2202MT

Specification

| Ordering Code | Insert ISO Code | Dimension | |||

|---|---|---|---|---|---|

| L;D | S | T | r | ||

| GW1667 | GFN3-MT | 9.50 | 2.50 | 3.0 | 0.20 |

| GW1088A | GTN3-MT | 10.70 | 2.50 | 3.0 | 0.20 |

| GW1553 | DGM3020CT | 20.00 | 5.00 | 3.0 | 0.40 |

| GW404 | DGM4020CT | 20.00 | 5.00 | 4.0 | 0.40 |

| GW1656 | DGM5025CT | 25.00 | 6.00 | 5.0 | 0.40 |

| GW1609 | DGM3020CTF | 20.00 | 3.00 | 3.0 | 0.40 |

| GW1598 | DGM4020CTF | 20.00 | 3.00 | 4.0 | 0.40 |

| GW1657 | DGM5025CTF | 25.00 | 5.00 | 5.0 | 0.40 |

| GW1669 | DGM3025CE | 25.00 | 5.00 | 3.0 | 0.40 |

| GW1793 | DGN3102MT | 20.00 | 6.20 | 3.10 | 0.25 |

| GW1828 | DGN2202MT | 20.00 | 6.05 | 2.20 | 0.20 |

Seeking Distributors for Partnership

- Technical support

- Education and training

- High-cost performance

- Flexible delivery time

- Complete supply chain

Long Plate Grooving Inserts | Guass Carbide Inserts – Engineered in Taiwan for Precision, Strength & Value

Enhance your machining accuracy and efficiency with high-performance Long Plate Grooving Inserts engineered by Guass. Designed to handle challenging materials and high-speed operations, our inserts deliver consistent results across turning, milling, and drilling applications.

Whether you're working with hardened steel, stainless alloys, or composites, our ISO-certified solutions are trusted by manufacturers in aerospace, automotive, electronics, and plastic injection molding industries. Each insert is crafted for longevity, excellent chip control, and minimal downtime—making your CNC process faster and more cost-effective.

With over 15 years of expertise in tungsten carbide sintering and tool innovation, Guass continues to set the standard for precision tooling. Explore our full selection of carbide inserts built for maximum durability and performance.