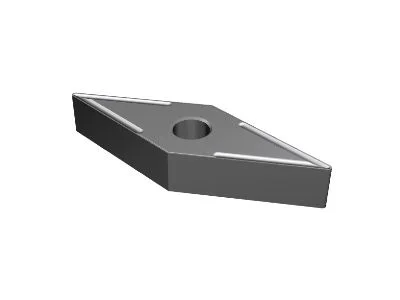

35 Degree Quadrilateral Turning Inserts

Adaptable to Mitsubishi Insert

The main cutting angle of 35 degree quadrilateral turning inserts are usually referred to as the negative angle. This is the angle of the cutting edge of the insert relative to the workpiece surface, which is tilted inwards.

The presence of a negative angle can reduce the cutting force between the insert and the workpiece and reduce heat concentration, thereby improving cutting efficiency and tool life.

Characteristics and Applications

The 35 degree quadrilateral insert is a cutting tool used for turning operations. Its cutting edge shape is rhombic. In general, the ISO code starts with a "v". It can be used on both sides. It has four cutting edges and chip flutes. There are many types of shapes and there are many types of cutting R angles. The type of flute used depends on the material being machined.

VN Type

- GW974-1, VNMG160404-FP

- GW974-BM, VNMG160404-BM

- GW1009, VNMG160408-FP

- GW1009-BM, VNMG160408-BM

Specification

| Ordering Code | Insert ISO Code | Dimension | |||

|---|---|---|---|---|---|

| D | S | r | d | ||

| GW974-1 | VNMG160404-FP | 9.52 | 4.76 | 0.4 | 3.8 |

| GW1009 | VNMG160408-FP | 9.52 | 5.76 | 0.8 | 3.8 |

Seeking Distributors for Partnership

- Technical support

- Education and training

- High-cost performance

- Flexible delivery time

- Complete supply chain

35 Degree Quadrilateral Turning Inserts | Guass Carbide Inserts – Engineered in Taiwan for Precision, Strength & Value

Enhance your machining accuracy and efficiency with high-performance 35 Degree Quadrilateral Turning Inserts engineered by Guass. Designed to handle challenging materials and high-speed operations, our inserts deliver consistent results across turning, milling, and drilling applications.

Whether you're working with hardened steel, stainless alloys, or composites, our ISO-certified solutions are trusted by manufacturers in aerospace, automotive, electronics, and plastic injection molding industries. Each insert is crafted for longevity, excellent chip control, and minimal downtime—making your CNC process faster and more cost-effective.

With over 15 years of expertise in tungsten carbide sintering and tool innovation, Guass continues to set the standard for precision tooling. Explore our full selection of carbide inserts built for maximum durability and performance.